Metallurgical Crane metallurgical single beam crane application

scope:

1. It is suitable for lifting molten metal in metallurgy and

foundry.

2. It is forbidden to use in inflammable, explosive and corrosive

medium environment.

Metallurgical single beam crane product description:

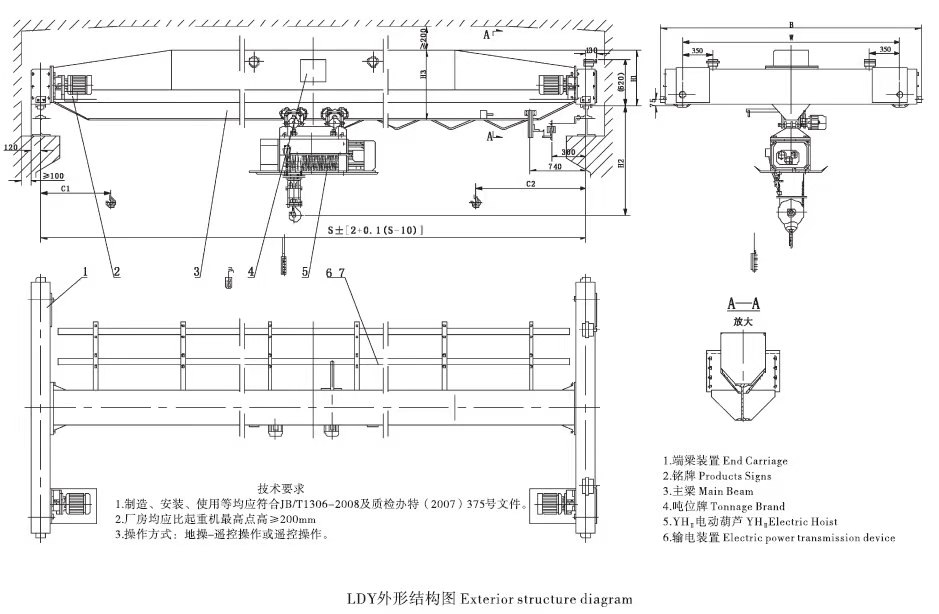

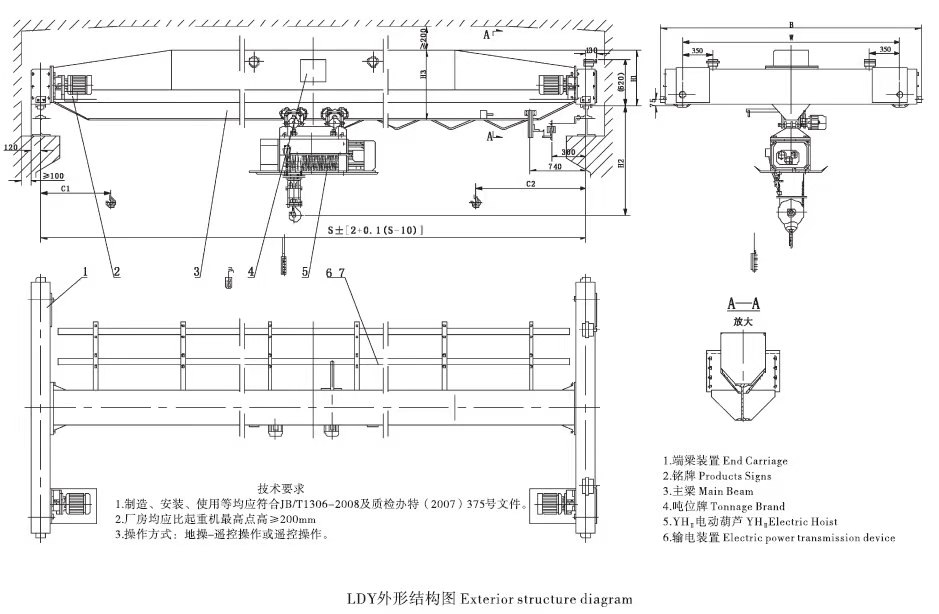

1. According to JB / t1306-2008 "electric single beam crane",

quality inspection office (2007) 375 "notice on metallurgical crane

rectification work" and tsgq0002-2008 "crane safety technology

supervision regulation bridge crane", it is designed and

manufactured with reasonable structure and strong rigidity.

2. The whole machine is used with YH metallurgical electric hoist.

3. The lifting capacity is 2-16 tons, the applicable span is

7.5-28.5 meters, the working level is A5, and the working

environment is in the range of - 20 ℃ ~ + 60 ℃.

4. According to the needs of the customer's site conditions, the

crane can be equipped with frequency conversion, lifting frequency

conversion or double speed hoist to make the crane run smoothly and

reliably.

5. Advantages: short order cycle, economical.

6. Disadvantages: relatively large shaking in use, low working

level, not suitable for heavy workshop.

Product identification:

Example: lifting capacity: 10t, span: 22m, lifting height: 9m,

working level: A5, expression method: ldy10-22 A5

Optional items

1. Working power supply: 380V / 400V / 415V / 660V? 50HZ/60HZ.

2. Operation mode: the product has three operation modes: ground

operation, remote control operation and operation room operation,

so as to meet the needs of users.

Technical parameters and application of metallurgical casting crane

Metallurgical crane is to rely on the longitudinal movement along

the plant rail direction, the transverse movement of the trolley

and the lifting movement of the hook to work. It is a special crane

for lifting molten metal in accordance with JB / t7688.1-95 and JB

/ t7688.15-95 standards. The application of metallurgical crane is

generally applicable to the ambient temperature from - 10 ℃ to + 50

℃, and the relative humidity is not more than 50?, under the

temperature of 40 ℃?, The radiation temperature of the molten metal

hoisted to the forging hook and plate hook shall not exceed 300 ℃.

Working level: A7, a8 for relatively busy metallurgical foundry.

Scope of application editing

Metallurgical crane is mainly used for metal smelting, rolling and

hot working. It includes open hearth charging bridge crane, ground

charging crane, charging box crane, ingot removal crane, mould

crane, uncovering crane, clamp crane, slab turnover crane, forging

crane, heating furnace charging and reclaiming crane, charging box

electromagnetic crane, charging box grab crane. Other similar

metallurgical cranes can also be used as reference.

Use condition edit

The design and manufacture of metallurgical crane (hereinafter

referred to as crane) shall comply with the relevant provisions of

gb3811, this standard and product drawings.

1. Environmental conditions

1.1 the power supply of crane is generally three-phase AC, with

frequency of 50 Hz and voltage of 380 v. The upper limit of

allowable voltage fluctuation on motors and electrical appliances

is + 10% of the rated voltage, and the lower limit (at peak

current) is - 15% of the rated voltage. The internal voltage loss

of cranes shall not exceed 5% for ingot stripping crane, clamp

crane, integral mold crane with guide frame and slab turnover

crane, and shall not exceed 4% for other types of cranes in this

standard.

If the power supply has special requirements, it can be determined

by the supplier and the demander through negotiation according to

the user's needs.

1.2 the altitude of the place where the crane is installed and used

shall not exceed 2000m (when it exceeds 1000m, the motor capacity

shall be checked according to the relevant provisions of gb755)

1.3 working environment temperature and humidity of crane

a. The working environment temperature of crane is generally - 10 ~

+ 50 ℃.

b. The relative humidity should not exceed 50% at + 40 ℃.

1.4 the site where the crane is used shall be free of inflammable,

explosive and corrosive gases and shall comply with relevant

standards and documents

1.5 the installation of crane running track shall generally meet

the requirements of gb10183. In case of special circumstances, it

can be specified separately

| Cargo port | Tianjin, Shanghai, Qingdao |

| cycle | 40-60 days |

| transaction mode | Cash delivery |

| Technical parameters of metallurgical electric single beam crane |

| Lifting capacity (T) | 3 | 5,10 |

Crane Operating mechanism | Operating speed (m/min) | 20 | 20 |

| Motor | model | YZDY21-4 | YZD32-4 |

| Power (kw) | 2*0.8 | 2*4.5 |

| Speed (RPM) | 1380 | 1400 |

| Lifting mechanism (electric hoist) and electric hoist operating

mechanism | Form of electric hoist | HYJI/II | HYJI/II |

| Lifting speed (M / min) | 4.8 | 4.8 |

| Lifting height (m) | 6~9~12~18 |

| Running speed (M / min) | 20 |

| Motor | Metallurgical tapered squirrel cage |

| working system | A5 |

| Power Supply | 3-phase 380V 50Hz |

| Wheel diameter | Ø270mm | Ø370mm |

| Track width | 37-70mm |

| | | | | |

Casting crane drawing►

A variety of products for customers to choose from►

Production site and international certification►